Incremental encoders are vital components in automation and control systems, providing accurate feedback on speed. From industrial robots to automated conveyor belts, their utility is widespread and indispensable in countless sectors.

They are especially valued for their simplicity, cost-effectiveness, and compatibility with numerous mechanical and digital systems.

What are Incremental Encoders?

An incremental encoder is a type of encoder that generates pulse signals in response to movement. Unlike absolute encoders that provide a unique position value, incremental encoders deliver pulses to indicate speed.

These encoders are commonly found in automation, motor feedback, and printing machines, among others. They are often used when sufficient and high-speed feedback is essential.

Components of an Incremental Encoder

Understanding the key components helps in evaluating encoder performance and reliability. Here are the essential parts:

- Shaft: Central rotating part often mounted on a motor. It transfers the rotational motion to the code disk. Encoder with wheels may attach to shafts for linear motion detection.

- Code Disk: A disk made of glass or plastic with alternating transparent and opaque lines. It defines the resolution and is integral to signal generation.

- LED Light Source: Emits a beam that passes through the code disk. It’s an essential part of an optical encoder setup.

- Photodetector/Photosensor: Converts light pulses into electrical signals as the disk rotates.

- Signal Conditioning Circuit: Amplifies and formats the signals from the photosensor to make them compatible with external controllers.

- Housing: Encases the components to protect them from dust, moisture, and mechanical damage. Often made from industrial-grade aluminum or stainless steel.

Credit: MDPI

How Do Incremental Encoders Work?

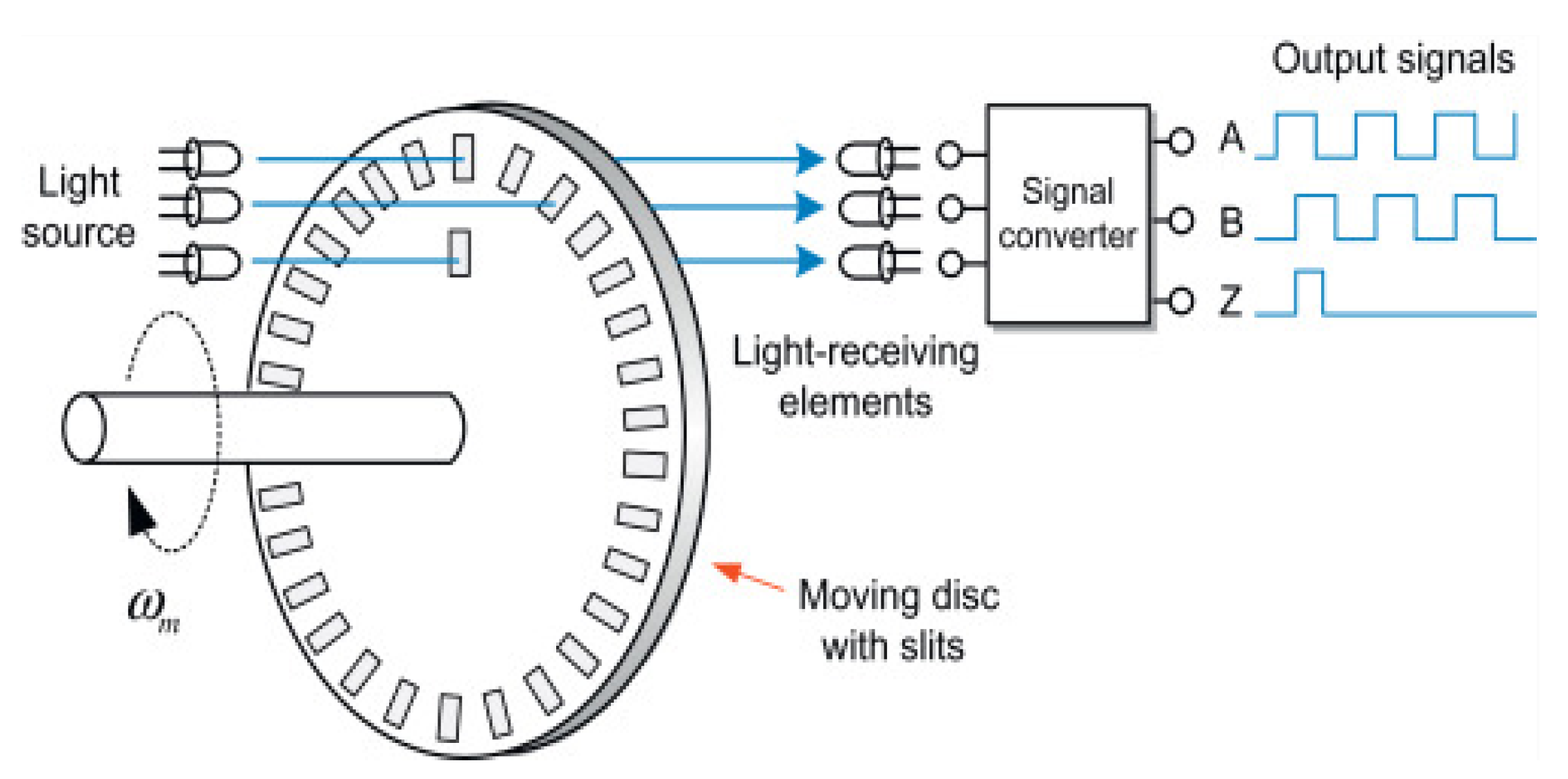

The working principle of an incremental encoder revolves around generating pulse signals when movement occurs. Here’s a breakdown of how it operates:

- Code Disk Movement: The incremental encoder contains a code disk attached to a rotating shaft. This disk has evenly spaced transparent and opaque areas that represent pulse segments.

- Light Source and Sensor: In most incremental rotary encoders, an LED light passes through the disk onto a photosensitive sensor. Each change in the pattern (from transparent to opaque or vice versa) generates an electrical pulse.

- Pulse Generation: A pulse is generated every time the encoder disk rotates and a light beam passes through a transparent section. The total number of pulses per revolution (PPR) defines the encoder’s resolution.

- Quadrature Outputs: Incremental encoders typically produce two square wave outputs (channels A and B), shifted 90 degrees apart. This helps in determining the direction of rotation.

- Optional Index Channel (Z): Some incremental shaft encoders have an additional index or reference pulse per revolution. This Z-channel indicates a fixed reference point used for calibration.

- Signal Processing: The output pulses are sent to controllers, which interpret the number and frequency of pulses to calculate speed, direction, and relative position.

- No Position Memory: One limitation of incremental encoders is their lack of memory. If power is lost, position tracking is reset unless additional systems back it up

Applications of Incremental Encoders

Incremental encoders are used across various sectors where motion feedback or speed monitoring is required.

Industrial Automation and Robotics

- In industrial robotics, incremental encoders provide feedback for precisely positioning robotic joints and arms. They enable real-time monitoring of angular displacement, which is crucial for manufacturing automation, welding, assembly, and inspection systems.

Printing and Textile Machinery

- Incremental rotary encoders are extensively used in printing presses and textile machinery to ensure synchronization between rollers, print heads, and feeding mechanisms. Even minor variations can lead to misalignment, which these encoders help prevent.

Conveyor and Packaging Systems

- In automated packaging lines, encoders help monitor conveyor speed and the length of material dispensed. They provide the necessary feedback for cutting, sealing, or labeling processes to be timed perfectly.

CNC Machines and Servo Motors

- Incremental shaft encoders are crucial for CNC machines and motor applications. They assist in motor feedback, enabling smooth operation and consistent torque control, especially in high-speed machining environments.

Steel Manufacturing

- In steel plants, incremental encoders help monitor the movement of motor rollers and cranes. They ensure speed regulation of motor-driven systems, aiding in transport operations in harsh industrial environments.

Rolling Mills

- Incremental rotary encoders are essential in rolling mills to measure the rotational speed of rollers. Accurate feedback allows for precise thickness control, reducing waste and improving product consistency in high-temperature operations.

Types of Incremental Encoders

Incremental encoders come in various formats depending on the application’s needs. Here are the two main types:

1.) Rotary Incremental Encoder

These encoders are attached to rotating shafts and provide pulses per revolution to track speed and position. They’re widely used in motors, robotics, and conveyors where rotational movement is central to operations.

2.) Linear Incremental Encoder

These encoders translate linear motion into incremental pulses. They are ideal for positioning systems, inspection equipment, and automation lines that require high accuracy in straight-line movement.

Difference Between Absolute and Incremental Encoders

- Position Tracking: Absolute encoders retain position data even when power is lost, while an incremental encoder requires rehoming after a reboot, as they only provide relative movement data.

- Signal Type: Incremental encoders output pulses (digital counts) for every movement, whereas absolute encoders output a unique code corresponding to each shaft position.

- Cost and Complexity: Incremental encoders are generally more straightforward and cost-effective than absolute encoders, which require more complex electronics and calibration.

- Application Suitability: Absolute encoders are best suited for safety-critical or position-sensitive tasks, while incr encoders are ideal for speed feedback and repetitive motion monitoring.

- Power Failure Recovery: An absolute encoder continues where it left off after a power failure, while an incremental encoder has to start from a reference or home point.

- Data Resolution: Although both can offer high resolutions, absolute encoders are preferred for exact and multi-axis control because they provide accurate position data.

Conclusion

Incremental encoders are indispensable for industries requiring real-time motion tracking and feedback. Their cost-efficiency, reliability, and versatility make them ideal for countless control and automation tasks. Despite their need for referencing after power loss, their advantages often outweigh this minor drawback.

Manglam Electricals provides a wide range of these devices, including incremental rotary encoder and incremental shaft encoder models. Designed for robust industrial use, Manglam’s encoders deliver precision, reliability, and compatibility with diverse automation systems, making them a trusted partner for manufacturers across sectors.

Leave a Reply